I.Introduction

With the wide application of lithium batteries in the lithium battery industry, requirements for high performance, high reliability and high cost performance are also put forward for battery management systems. This product is a BMS specially designed for lithium batteries. It can collect, process and store the information and data of the battery pack in real time during use to ensure the safety, availability and stability of the battery pack.

II.Product Overview and Features

1. Using professional high-current trace design and technology, it can withstand the impact of ultra-large current.

2. The appearance adopts the injection molding sealing process to improve moisture resistance, prevent the oxidation of components, and prolong the service life of the product.

3. Dustproof, shockproof, anti-squeezing and other protective functions.

4. There are complete overcharge, over-discharge, over-current, short circuit, equalization functions.

5. The integrated design integrates acquisition, management, communication and other functions into one.

6. With communication function, parameters such as over-current, over-discharge, over-current, charge-discharge over-current, balance, over-temperature, under-temperature, sleep, capacity and other parameters can be set through the host computer.

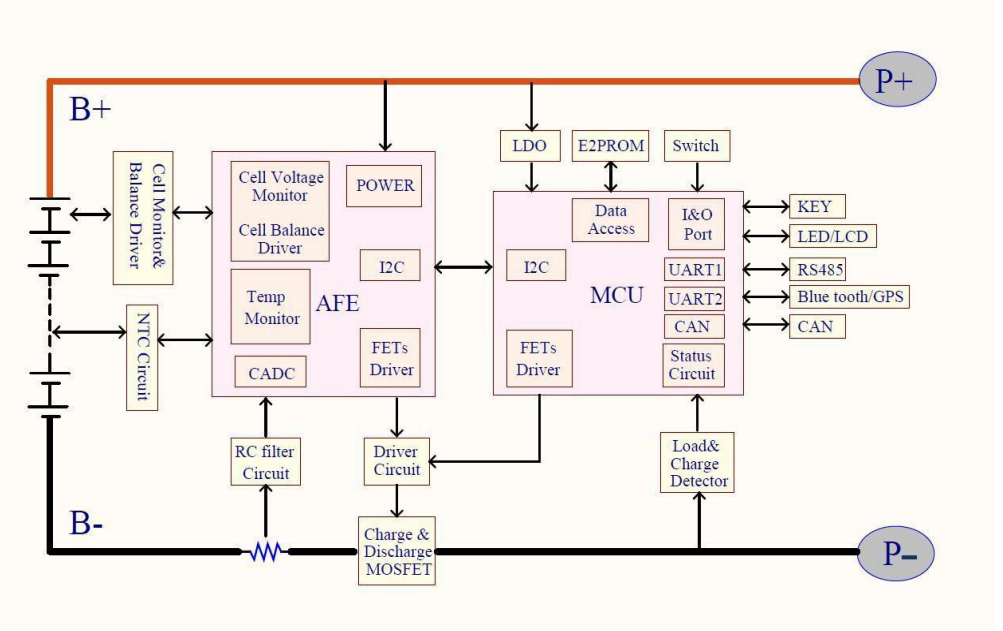

III. Functional Schematic Block Diagram

IV. Communication Description

The default is UART communication, and communication protocols such as RS485, MODBUS, CAN, UART, etc. can be customized.

1.RS485

The default is up to the lithium RS485 letter protocol, which communicates with the designated host computer through a special communication box, and the default baud rate is 9600bps. Therefore, various information of the battery can be viewed on the host computer, including battery voltage, current, temperature, state, SOC, and battery production information, etc., parameter settings and corresponding control operations can be performed, and the program upgrade function can be supported. (This host computer is suitable for PCs of Windows series platforms).

2. CAN

The default is lithium CAN protocol, and the communication rate is 250KB/S.

V. PC software Description

The functions of the host computer DALY BMS-V1.0.0 are mainly divided into six parts: data monitoring, parameter setting, parameter reading, engineering mode, historical alarm and BMS upgrade.

1. Analyze the data information sent by each module, and then display the voltage, temperature, configuration value, etc.;

2. Configure information to each module through the host computer;

3. Calibration of production parameters;

4. BMS upgrade.

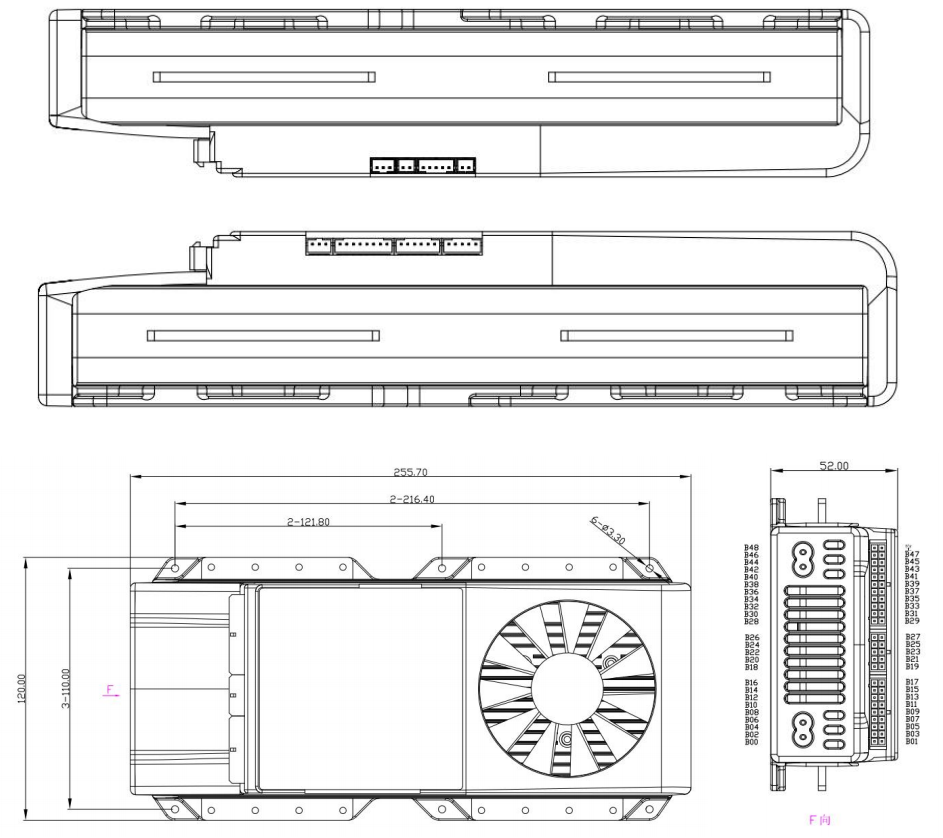

VI. Dimensional drawing of BMS(interface for reference only, unconventional standard,please refer to Interface pin specification)

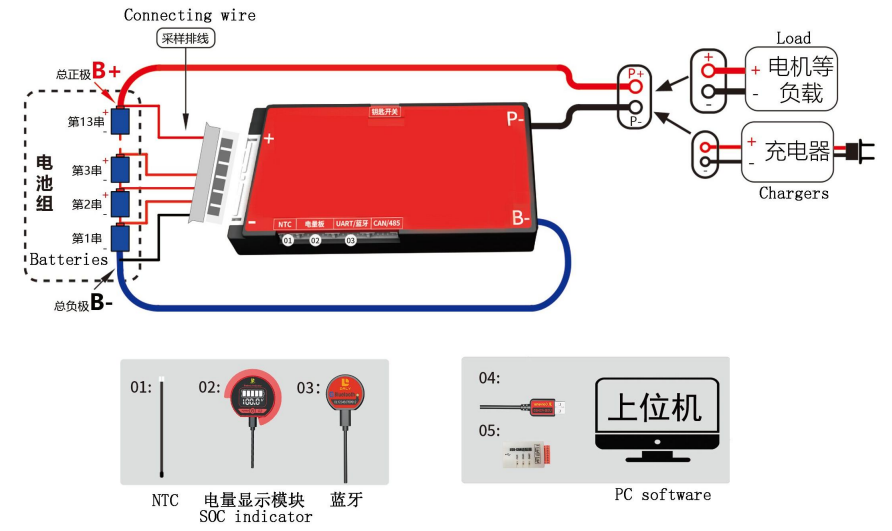

VIII. Wiring Instructions

1. First connect the B-line of the protection board (thick blue line) to the total negative pole of the battery pack.

2. The cable starts from the thin black wire connected to B-, the second wire is connected to the positive electrode of the first string of batteries, and the positive electrode of each string of batteries is connected in turn; then insert the cable into the protection board.

3. After the line is completed, measure whether the voltages of battery B+ and B- are the same as those of P+ and P-. The same means that the protection board is working normally; otherwise, please re-operate according to the above.

4. When removing the protection board, first unplug the cable (if there are two cables, first pull out the high-voltage cable, then pull out the low-voltage cable), and then disconnect the power cable B-.

IX. Wiring Precautions

1. Software BMS connection sequence:

After confirming that the cable is welded correctly, install the accessories (such as standard temperature control/power board option/Bluetooth option/GPS option/display option/custom communication interface option) on the protection board , and then insert the cable into the socket of the protection board; the blue B-line on the protection board is connected to the total negative pole of the battery, and the black P-line is connected to the negative pole of charge and discharge.

The protection board needs to be activated for the first time:

Method 1: Activate the power board. There is an activation button on the top of the power board. Method 2: Charge activation.

Method 3: Bluetooth Activation

Parameter modification:

The number of BMS strings and protection parameters (NMC, LFP, LTO) have default values when they leave the factory, but the capacity of the battery pack needs to be set according to the actual capacity AH of the battery pack. If the capacity AH is not set correctly, then The percentage of remaining power will be inaccurate. For the first use, it needs to be fully charged to 100% as a calibration. Other protection parameters can also be set according to the customer's own needs (it is not recommended to modify the parameters at will).

2.For the wiring method of the cable, refer to the wiring process of the hardware protection board on the back. The smart board APP modifies the parameters. Factory password: 123456

X. Warranty

All lithium battery BMS produced by our company has a one-year warranty; if the damage caused by human factors, paid maintenance.

XI. Precautions

1. BMS of different voltage platforms cannot be mixed. For example, NMC BMSs cannot be used on LFP batteries.

2. The cables of different manufacturers are not universal, please make sure to use our company's matching cables.

3. Take measures to discharge static electricity when testing, installing, touching and using the BMS.

4. Do not let the heat dissipation surface of the BMS directly contact the battery cells, otherwise the heat will be transferred to the battery cells and affect the safety of the battery.

5. Do not disassemble or change BMS components by yourself.

6. The company's protective plate metal heat sink has been anodized and insulated. After the oxide layer is damaged, it will still conduct electricity. Avoid contact between the heat sink and the battery core and nickel strip during assembly operations.

7. If the BMS is abnormal, please stop using it and use it after the problem is solved.

8. All lithium battery protection boards produced by our company are guaranteed for one year; if damaged due to human factors, paid maintenance.

XII. Special Note

Our products undergo strict factory inspection and testing, but due to the different environments used by customers (especially in high temperature, ultra-low temperature, under the sun, etc.), it is inevitable that the protection board will fail. Therefore, when customers choose and use BMS, they need to be in a friendly environment, and select a BMS with a certain redundancy capability.

Post time: Sep-06-2023