Overview

The parallel current limiting module is specially developed for PACK parallel connection of

Lithium battery Protection Board. It can limit the large current between PACK due to

internal resistance and voltage difference when PACK is parallel connected, effectively

ensure the safety of the cell and the protection plate.

Characteristics

v Easy installation

v Good insulation, stable current, high safety

v Ultra-high reliability testing

v The shell is exquisite and generous, full-enclosed design, waterproof, dust proof, moisture-proof, extrusion-proof and other protective functions

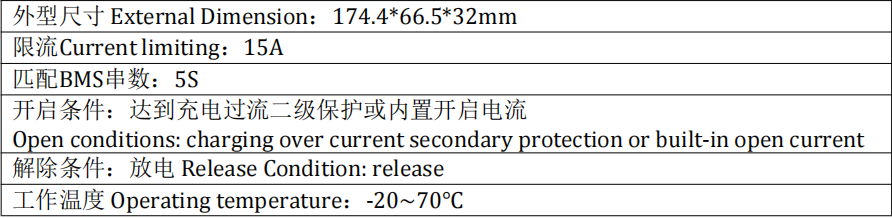

Main technical instructions

Function description

v Prevent PACKs from being recharged with large currents due to differences in internal resistance and voltage when they are connected in parallel.

v In case of parallel connection, different pressure difference causes charge between battery packs

v Limit the rated charging current, effectively protect the high current protection board and Battery

v Anti-sparking design, the battery pack connected in parallel with 15A will not cause sparking.

v Current limiting indicator light, when the trigger current limiting is turned on, the indicator light on the parallel protector is l

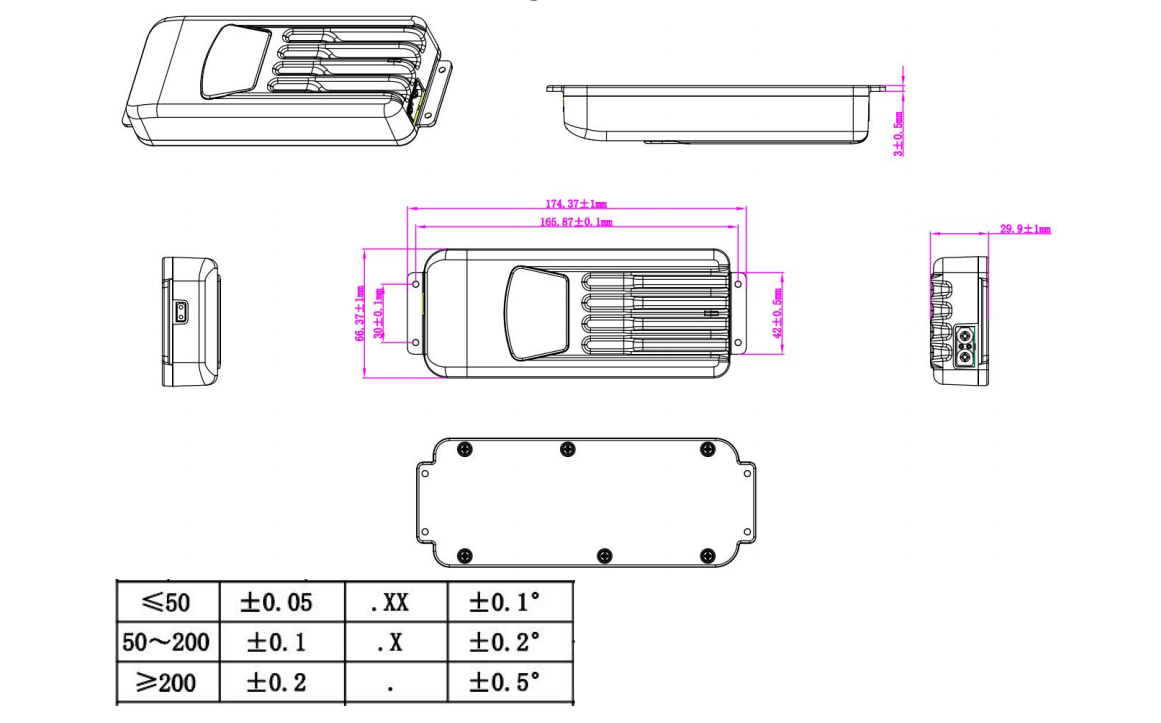

Dimensional drawing

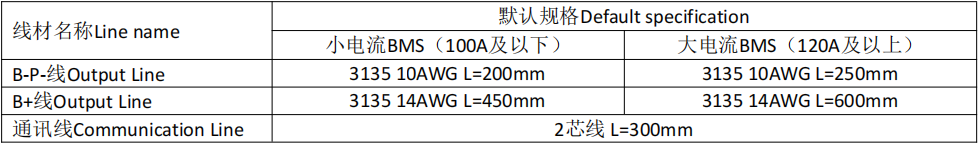

Main wire description

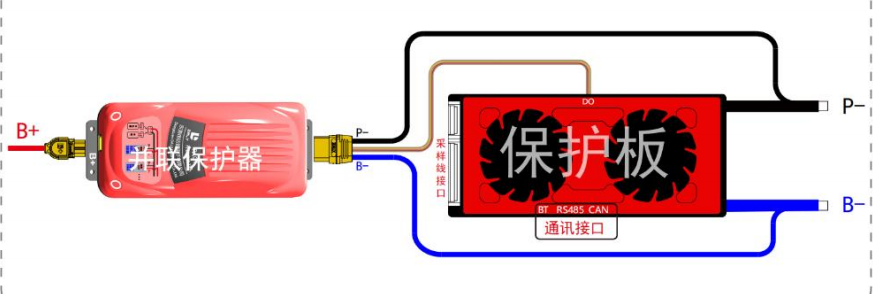

Pack parallel connection BMS Wiring Diagram

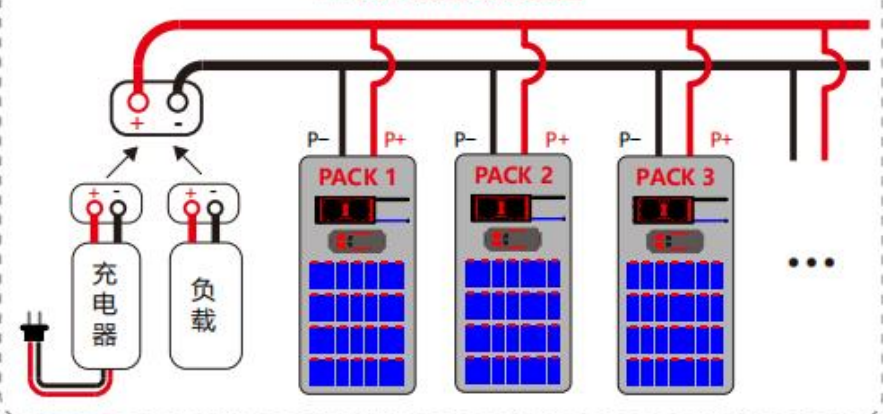

v Pack Parallel Protection Board by the protection board + parallel module of two parts, that is, each need to parallel PACK must contain these two parts

v which protect board detailed wiring to check the protection board specifications;

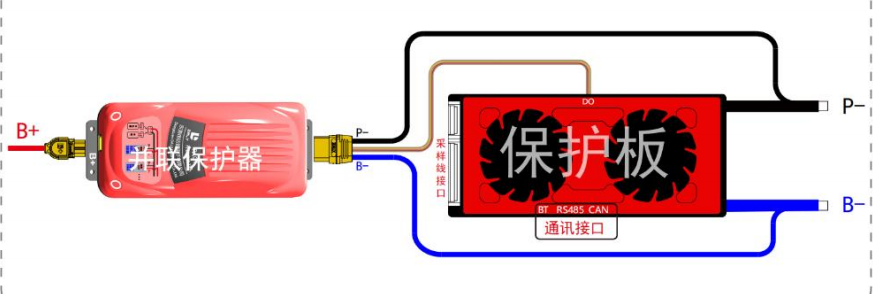

v Each PACK internal guard panel is connected to the parallel module in the following manner:

Multiple packs are connected in parallel as shown below:

Wiring matters needing attention

v After the assembly of BMS is completed when the parallel protector is connected with the protective plate, it is necessary to connect the p-line to the C-OF BMS, then to B-, then to B + , and finally to the control signal line.

v The B-/p-plug of the parallel module should be connected first, then the B + Plug, and then the control signal wire should be connected.

v Please strictly in accordance with the wiring sequence operation, such as wiring sequence reversed, will lead to PACK parallel protection board damage.

v CAUTION: BMS and shunt protector must be used together and not intermixed

Warranty

The company’s production of parallel PACK module, we guarantee 3 years warranty in quality, if the damage is caused by human improper operation, we will conduct repair with charge.

Post time: Sep-20-2023